News

Freshman Kaylee Cornelius works on her final project for Introduction to Electrical Engineering (ES 50) on her family's dining room table. (Photo provided by Kaylee Cornelius)

On a typical spring afternoon, the Active Learning Labs at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) are buzzing with students crafting devices or working through lab assignments—some use a laser-cutter to make components for a wheeled robot, others solder electronic components onto a printed circuit board, while others prepare reagents for cell culturing.

This spring, the labs are empty.

The University’s decision to “de-densify” the campus to prevent the spread of COVID-19 effectively shuttered the labs and altered the way hands-on engineering courses would need to be taught.

With only three days between the March 10 announcement and students’ departure from campus, staff and faculty rushed to find innovative ways to rework labs so students could complete them at home.

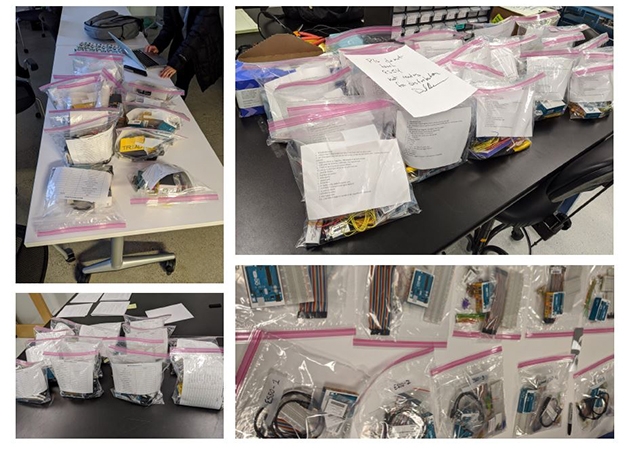

“Within 72 hours, we engaged with faculty on content development, working with key stakeholders to order items they requested, preparing those components, writing instructions for them, and then packing it all up into zip lock bags that we could send home with the students, all while keeping safety in mind,” said Anas Chalah, Assistant Dean for Teaching and Learning. “Even with a very truncated timetable, the staff managed to put all that together in a very elegant way.”

A take-home kit for Electronics for Engineers (ES 54) contains resistors, capacitors, integrated circuits, Arduino microcontrollers, wire cutters, and a multimeter students can use to measure electronic signals. Students use those tools during lab sessions on Zoom, building and testing electronics circuits, like heart rate monitors, under the guidance of faculty and teaching fellows, explained Munib Wober, Teaching Labs Design Specialist.

For Introduction to Electrical Engineering (ES 50) the staff found a unique device that contains an oscilloscope, function generator, and digital logic analyzer, all in a package that can connect to a computer via USB or WiFi. The miniature device has proven to be extremely useful, since students aren’t able to access the powerful, bench-top tools they’d typically have in the lab, said Christopher Lombardo, Associate Director of Undergraduate Studies in Electrical and Mechanical Engineering.

In only 72 hours, the Active Learning Labs staff put together these take-home kits for students in project-based courses so they could continue to work on projects at home. (Photo provided by the Active Learning Labs)

While the students' final projects may be different than in years past, that doesn’t mean the projects are any less creative.

For instance, one of Lombardo’s students, an athlete who has found herself with more free time now that there are no games or practices, has taken up baking. But her family members keep eating all the cookies she makes. For her final ES 50 project, she is incorporating a weight sensor and an accelerometer into her cookie jar so that an alarm sounds whenever someone tries to steal a treat.

Social distancing doesn’t have as much of an impact on ES 50 projects because students complete them individually this year. Projects that require remote collaboration pose an entirely different set of challenges. In Engineering Problem Solving and Design Project (ES 96), for example, students work in a team to develop a project that meets the needs of a real-world client.

During the last in-person ES 96 class on March 11, Nabil Harfoush, Visiting Associate Professor in Engineering Sciences, and his students wondered how they could collaborate when they were scattered all over the country. Harfoush challenged the students to come up with a solution.

They sprang into action, fast-tracking the development of specifications for the project and conceiving a fair system for dividing the workload. Students who would be fabricating components were sent home with the tools they needed. The Active Learning Labs staff ordered and had shipped directly to students’ homes the sensors and other components required for the prototype.

Using Zoom and a class Slack channel, the students shared insights and assistance as they worked individually to fabricate some components. They then shipped the pieces to a student living in Chicago, who is tasked with completing the final assembly and testing the device, which uses sensors to determine the ripeness of avocados.

“Even virtually, they help each other. When one person is facing a problem, everybody puts in the maximum effort to come up with a solution. They have a very professional attitude,” Harfoush said. “They came together in this challenge. The students didn’t give up on providing a solution to the client.”

Harfoush’s ES 96 section will still produce a physical device, but some instructors were forced to completely change how final projects are structured.

Students, faculty, and staff participate in a virtual design review session for Computer-Aided Machine Design (ES 51). (Image provided by Michelle Rosen)

Students in Computer-Aided Machine Design (ES 51) typically spend the term designing and fabricating a wheeled robot. The course culminates in a “Turf Wars” competition that pits the task-completing robots against one another in a competition arena.

But without the 3D printers and laser cutters, and the machine shop with its mills, lathes, and drill presses, students have no way to build the robots at home.

The students had been working toward the construction of gear boxes for their robots, which they were about to complete before the campus was shut down. In an effort to give them a sense of what they would have done in the lab, Elaine Kristant, Manager of Active Learning and Student Engagement, rushed back to campus before the labs were closed and recorded a video explaining what the students would have built using a demo gear box.

In its remote form, the course now involves more computer-aided design (CAD) work and weekly design reviews. And instead of a final robot battle, the students will pitch their conceptual robots in a “Shark Tank” style contest.

“Each team will present their robot to us and prove that it is the best robot for the job, and we’ll invest our money accordingly,” said Michelle Rosen, Lecturer in Mechanical Engineering Design. “That way, there will still be a fun competition element behind the course.”

Other hands-on courses also required staff and faculty to completely re-think what lab work could look like in a virtual environment. The labs for Tissue Engineering (BE 125), for instance, require a tissue culture hood and certain chemicals that a student absolutely could not take home, said Melissa Hancock, Biological and Environmental Lab Engineer.

Students were in the middle of an experiment when they were required to leave campus and rewriting the lab midstream was not an option. Instead, she and David Mooney, Robert P. Pinkas Family Professor of Bioengineering, had the students finish the experiment by writing it as a grant, focusing on the particulars of experimental design, graphical presentation of data, and effective techniques to communicate results to an audience.

The focus on data analysis and numerical simulation is going to come out of this as a strength. If we are teaching remotely in the future, these are the things we are really going to want to build on.

As they have moved online, many project-based courses now focus more on computation.

Students may have the chance to explore a software package like COMSOL in a different way. Rather than learning the subtleties of conducting a lab in person, they think more critically about what to do with the results once they obtain them, said Patrick Ulrich, Director of Undergraduate Education.

“The focus on data analysis and numerical simulation is going to come out of this as a strength. If we are teaching remotely in the future, these are the things we are really going to want to build on,” he said. “We need to ask ourselves—what did we learn this semester that changed how students engaged in the lab or how they thought about it that would make sense even when we are back on campus? There may be new numerical simulations that we thought weren’t necessary but that could become a core of what we do. Or maybe we’ll see the value in having that data analysis experience? Things are going to be different moving forward, so this was a great time to pilot something, and then we can be more thoughtful about implementing it fully.”

For Eric Mazur, Balkanski Professor of Physics and Applied Physics, the process of moving his popular course Physics as a Foundation for Science and Engineering (AP 50) online provided a golden opportunity to re-think everything about teaching.

Mazur adjusted the way the course is typically taught by making the lectures self-paced and asynchronous, but bringing students together for collaborative work to ensure they understand the concepts and maintain social connection.

Eric Mazur's home set-up enables him to easily monitor student feedback during virtual sessions of Physics as a Foundation for Science and Engineering (AP 50). (Photo provided by Eric Mazur)

The course centers around peer instruction, so students use Perusall, a social document annotation platform, to read the textbook on their own. The platform enables them to highlight what they don’t understand, post questions, answer each other, and invoke each other’s help, he explained.

During class time, Mazur uses Zoom to show video demonstrations of physics concepts. For instance, he set up a series of glasses on his desk with different amounts of water to illustrate the principle of refraction. Then he asks a question and splits teams of students into breakout rooms to come up with an answer. Mazur will “hop” from room to room to check in, just like he would move between tables in a flexible classroom.

The entire structure is different, but it seems to be working very well, he said.

“Usually the pace of the instructor doesn’t match the pace at which the student is learning, but most of our activities are instructor-paced, as if education was a sort of conveyor belt where everybody moves at exactly the same pace together. In reality, some people will go a little bit faster and others will go a little bit more slowly, and their pace will change,” he said. “As I had to move all of these components online, I thought the more that I could move synchronous activities to be asynchronous, and instructor-paced to self-paced, the more I could improve education, because now I match what the student needs are, and I also free up my time to help students where it really matters.”

In Product and Experience Design for Desirability (ES 22), Beth Altringer, Senior Preceptor in Innovation and Design and core faculty member of Harvard’s MS/MBA program, is also using innovative online tools to make virtual instruction easier for her students.

“Typically, by this point in the course, students spend most of their time problem-solving and doing design critiques around white boards or learning fabrication skills in workshops that we offer outside of class to help them build their prototypes,” she said. “Neither whiteboards nor fabrication workshop spaces are available now, so I had to find new digital spaces that recreate these functions.”

She has set up a nested visual workspace using the web-based software Milanote for students to work on their final group projects. Milanote boards let students not only visualize ideas, but also add links and files with visual thumbnails, comment on project elements, and assign tasks and deadlines. Altringer has found that the platform helps all students have a more equal voice compared to live classroom settings. It also makes it easier to get a better sense of each student’s overall work in a way that wouldn’t be possible during an in-person class, she said.

This has extended my ability to give them hands-on instruction outside of class time and to provide a cohesive shared experience.

To replicate the functionality of fabrication workshops that she normally offers in person, Altringer chose to focus on digital fabrication in a virtual environment. She tried a few existing online 2D/3D Unity courses herself before choosing one that would integrate best with the class. She uses it as supplementary workshop material that lets students in any time zone improve their prototyping skills at their own pace, with very clear milestones from the teaching staff.

At his home in Chicago, mechanical engineering concentrator John Schmidt, S.B. '21, integrates the instrument he and his ES 96 classmates designed and built. (Photo provided by John Schmidt)

“This has extended my ability to give them hands-on instruction outside of class time and to provide a cohesive shared experience,” she said. “Students are still building their own projects and we are meeting our original learning experience goals, but our methodology and support tools have changed. I would never have thought to embed Milanote nor a supplementary online course inside my course, but it has been fun, and both are working really well.”

As faculty, staff, and students continue to adjust to this new mode of virtual learning, Ulrich said the administration is preparing to carefully evaluate what worked and what didn’t after the term concludes.

He understands the letdowns many students felt—especially seniors in Engineering Design Projects (ES 100), many of whom didn’t have time to put the finishing touches on their capstone projects before they left campus.

Yet despite the myriad challenges this spring, there have been a number of silver linings.

“Instructors often have a chance to drop into office hours now and interact with their teaching fellows and students. Faculty also find it easier to connect with students outside of hours now,” Ulrich said. “Despite the distance, we are seeing new ways of engaging with our students and our classes that hopefully will permeate.”

Topics: Academics

Cutting-edge science delivered direct to your inbox.

Join the Harvard SEAS mailing list.

Press Contact

Adam Zewe | 617-496-5878 | azewe@seas.harvard.edu