Follow along as Lyra Wanzer builds an electroadhesive treaded robot for her senior capstone project

Follow along as Lyra Wanzer builds an electroadhesive treaded robot for her senior capstone project

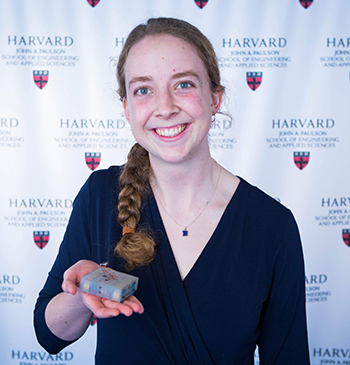

Lyra Wanzer, S.B. ‘19, concentrating in mechanical engineering at the Harvard John A. Paulson School of Engineering and Applied Sciences, built an electroadhesive treaded robot in the Microrobotics Laboratory of Robert Wood, Charles River Professor of Engineering and Applied Sciences, for her project in “Engineering Design Projects” (ES 100). The capstone course challenges seniors to develop a creative project that solves a real-world engineering problem.

Electroadhesive robots are very useful in exploring difficult to reach places for inspection, as well as search and rescue. Giving her robot the name μTER, Wanzer also gave it a combination of the advantages of different existing electroadhesive robots, such as a versatile, wheeled and treaded design, and the smaller design of the HAMR-E (Harvard Ambulatory Micro-Robot with Electroadhesion).

After many iterations on the tread design throughout the semester, Wanzer ultimately used a design with multiple layers. She laser cut the different layers, cured them with heat and pressure, and then release cut the parts she needed. She recessed copper foil, the dielectric used for electroadhesion, so that it would not react with the substrate.

In our most recent update with Wanzer, she was working through different prototypes of the drive system alignment that connected the treads of her robot. In her final product, she has added end caps to prevent the wheels from sliding sideways and optimized the length of couplings between the wheels to secure the drive system. She made carbon fiber bushings, bearings to reduce friction between different parts of the car. Wanzer tried different ways of cutting, finding that epoxy melted the strands and that the bushings were too small for a powder blaster. She ultimately used a diamond saw with a holder that she 3D printed. Wanzer constructed the wheels of the robot from two layers of compliant foam. She tried both a concave and a convex tread and found that a convex tread worked best for her robot.

In the final stages of building her robot, Wanzer evaluated the total mass of the robot, the wheel torque, the voltages, and safety. She added a top plate to make the chassis, the base frame, rigid to protect the robot during testing. She studied the speed of the robot while it pulled a load of varying mass behind it to optimize her system. As the angle of the inclined surface increased, the speed of her robot decreased. Moving on a 30 degree incline, her robot was much faster than other existing electroadhesive robots.

In the future, she would like to see further work done in making the robot lighter and better able to hold a greater load. Wanzer intends to publish her work to share her design with the robotics community. Grateful for the mentorship she received from her lab, the course staff, and the Active Learning Labs, Wanzer speaks highly of the learning experience of the capstone project. Like μTER, she looks forward to exploring new ground and embarking on the next steps of her journey in robotics.

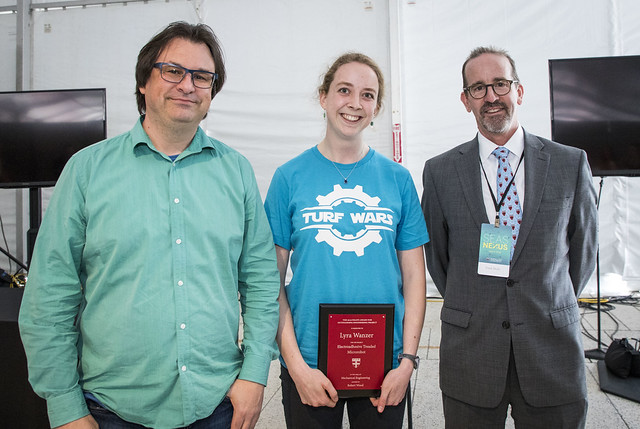

In recognition of her outstanding work over the course of the year, Wanzer was named winner of a Dean’s Award for Outstanding Engineering Projects, presented annually to students who are chosen by faculty members for having the best projects in ES 100.