News

The second annual MakeHarvard challenged more than 300 undergraduate and graduate students from some 50 universities to make their ideas into a reality. (Photo by Annie Schugart/SEAS Communications)

The second year of MakeHarvard, an annual engineering makeathon held at the Harvard John A. Paulson School of Engineering and Applied Sciences, challenged students to make their ideas a reality. More than 300 undergraduate and graduate students from some 50 universities embraced the opportunity.

There are many hackathons for students to practice their software skills, but hardware-focused makethons are far fewer. Stepping up to fill that need, MakeHarvard was founded last year to provide an intensive learning experience for student engineers. The MakeHarvard team provided mentors to answer students’ questions, ran workshops on engineering fundamentals and resume building, and raised tens of thousands of dollars from sponsors to provide hardware for students to use.

Students brainstorm potential solutions during MakeHarvad. (Photo by Annie Schugart/SEAS Communications)

Elton Lossner, S.B. ‘19, an electrical engineering concentrator and leader of the MakeHarvard team, said, “Building MakeHarvard required a lot of coordination between different people and sponsors. It was a very rewarding experience, and a great way to bond and make friends. We wanted to build the reputation of Harvard SEAS and show our capability to other schools.”

Jessica Han, S.B. ’20, a mechanical engineering concentrator and MakeHarvard sponsorship executive, said, “I’m glad we have the opportunity to build community among engineers, spread the name of Harvard engineering, and share resources with other schools.”

The LifeBattery team created a device to measure and report an individual's alertness. (Photo by Selena Zhang/SEAS Communications)

Life Battery

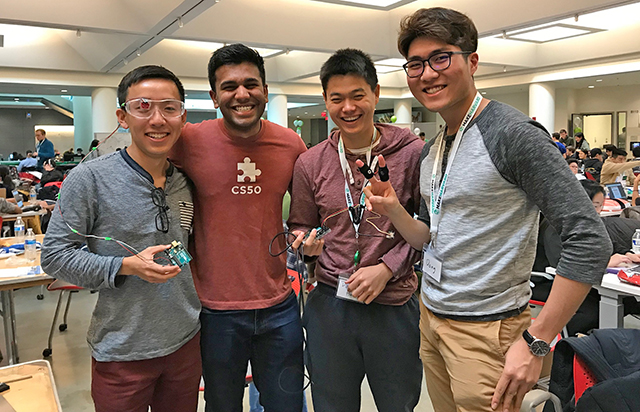

(From left) Andrew Yang, S.B. ’20, a bioengineering concentrator, Rohan Jha, S.B. ’20, a bioengineering concentrator, Darrell Huang, S.B. ’20, an electrical engineering concentrator, and Dong Hur, A.B. ’20, a neurobiology concentrator

The LifeBattery team worked to make a device to measure and report an individual's alertness so that wearers can better choose tasks to match their level of alertness, whether tackling a problem set or taking a needed nap. The eyepiece of this device measures the percent of time the wearer has his or her eyes closed. LifeBattery also measures skin conductivity, as higher skin conductivity has been associated with greater levels of alertness. These two metrics enable LifeBattery’s device to display a human ‘battery percentage,’ said Andrew Yang, S.B. ’20, a bioengineering concentrator.

The project was inspired by the need they saw in their own lives as students, said Rohan Jha, S.B. ’20, a bioengineering concentrator.

“Students try to optimize what to do based on their alertness. We hope this will help them make those decisions,” he said.

MakeHarvard participants wasted no time grabbing hardware and getting to work on their tools and devices. (Photo by Annie Schugart/SEAS Communications)

The team members applied the skills they learned in their studies at SEAS, from the fundamentals of circuits to laser cutting and computer-aided design (CAD). Combining their different backgrounds in electrical and bioengineering, they collaborated to build a working prototype.

“Seeing our device blinking and working was the most fun,” said Dong Hur, A.B. ’20, a neurobiology concentrator.

Buzzworks

Anthony Cheng, S.B. ’20, a materials science major at MIT, Lisa Wang, A.B. ’23, Ayush Ghosh, S.B. ’23, a mechatronics engineering major at University of Waterloo, and Guillaume de Cannart, S.B. ’21, a mechanical engineering major at Diablo Valley College in California

Many natural pollinators, such as honey bees, are dying off due to climate change, disease, and other factors. Hand pollination presents many challenges in an agricultural context. To combat those challenges, Buzzworks worked on building a robot that pollinates strawberry plants.

Anthony Cheng, S.B. ’20, a materials science major at MIT, explained that the team chose strawberries because the plants are uniform and easily identifiable using computer vision and artificial intelligence. Buzzworks developed a modular design for their robot, so that many replicates could be made and adapted for other plants.

Guillaume de Cannart, S.B. ’21, a mechanical engineering major at Diablo Valley College, said, “This is my first makeathon, though I’ve done coding hackathons before. I’m really excited to actually build stuff because it adds a dimension to the project beyond visualizing on a screen.”

These students developed an elbow band that can be used for physical therapy. (Photo by Selena Zhang/SEAS Communications)

Elbow band for physical therapy

(From left) Joseph Sanchez, S.B. ’21, a mechanical engineering concentrator, Jessica DeVilla, S.B. ’21, a bioengineering engineering concentrator, Patrick Poplawski, S.B. ’19, a manufacturing engineering major at University of Ontario, and Manikin Ho, S.B. ’19, a mechatronics engineering at University of Ontario

Tackling the challenge of improving physical health, a team at MakeHarvard worked to build an elbow band that can be used for physical therapy. Research from astronaut programs has shown that low-frequency vibrations have the potential to regenerate bone density. Jessica DeVilla, S.B. ’21, a bioengineering concentrator, explained that their team constructed a brace with haptic motors sewn into the fabric that could emit these low-frequency vibrations.

The team also worked to build a consumer-facing web application to track progress for the wearer. The weaer could then choose to send the collected information to his or her doctor to inform their treatment plan. The web app counts repeated motions in a set of exercises and assesses the wearer’s range of motion.

This team also had a stretch goal of incorporating a virtual reality display to track ideal arm motion, so a user can move his or her arms along the tracks of any exercises prescribed by their doctors. The team hopes that such an application will better inform health care provider decisions.

MakeHarvard mentors roved throughout Northwest Hall, providing advice and feedback to student makers. (Photo by Annie Schugart/SEAS Communications)

“I had a great time last year. I met a lot of great people, and I want to do the same this year,” said Joseph Sanchez, S.B. ’21, a mechanical engineering concentrator and previous winner of MakeHarvard.

Their team motto was “adapt and overcome,” fitting with the spirit of MakeHarvard.

Topics: Events

Cutting-edge science delivered direct to your inbox.

Join the Harvard SEAS mailing list.

Press Contact

Adam Zewe | 617-496-5878 | azewe@seas.harvard.edu