Materials science and mechanical engineering Ph.D. student Amanda Filie also enjoys the challenges and camaraderie of competitive ballroom dancing. (Photo courtesy of Peter Ung Photography.)

Amanda Filie’s lifelong love of chemistry began aboard a boat floating in the Chesapeake Bay.

She and her elementary school classmates tested the brackish water with pH paper, revealing abnormal acidity levels, an indication that pollutants were damaging the health of this critical marine ecosystem.

“I was fascinated by the idea that I could look at the water, and it seemed fine, but one little chemical test showed that the water is completely unacceptable for the local environment,” she said. “That experience got me thinking about life differently. What you see isn’t always what is going on physically, especially at the molecular level.”

That childhood realization has inspired Filie through middle and high school, college, and now as a materials science and mechanical engineering Ph.D. student at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS), where her research aims to reduce the carbon footprint of the chemical manufacturing industry.

Filie grew up about 30 minutes outside of Washington, D.C. Her lifelong interest in chemistry was sparked during a childhood trip to the Chesapeake Bay. (Photo courtesy of Amanda Filie.)

The Potomac, Md., native studied chemical engineering at the University of Maryland, College Park after witnessing the harsh effects of pollution firsthand.

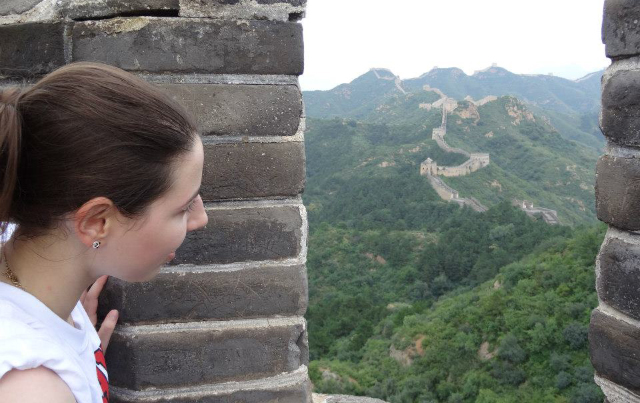

During family trips to Brazil, her father’s birthplace, Filie was shocked by the dark cloud of smog hanging over São Paulo. While visiting Beijing before her freshman year, she saw how severe air pollution causes a daily struggle for millions packed into overcrowded cities.

“That experience showed me that all of us, even though we are from different countries and different cultures, face many of the same challenges and value a lot of the same things,” she said.

As an undergraduate, she joined the lab of Assistant Professor Dongxia Liu and began studying a catalyst used in the development of biofuels.

Biofuels are produced when long chains of sugar in an organic substance like corn are chemically broken down and restructured so they burn like a fossil fuel, Filie explained. She studied zeolites, materials that can be engineered to facilitate chemical reactions, and focused on the role acidity plays in how quickly sugars decompose.

Hooked on research, Filie joined the Surface Science Group of Cynthia Friend, Theodore William Richards Professor of Chemistry and Professor of Materials Science, where she studies the chemical and physical properties of metal nanoparticles, and how these properties relate to the ability to catalyze reactions.

“For me, it is exciting to understand how things work, and it is particularly challenging when you can’t see what is going on,” she said. “There is a little bit of detective work involved when it comes to surface science.”

Filie explores the Great Wall of China during a trip that emphasized how severe air pollution negatively impacts the quality of life for many. (Photo courtesy of Amanda Filie.)

Her research centers on quantifying the properties of catalytic materials and elucidating their reaction pathways. These fundamental studies help inform the design of new catalysts that better serve the chemical industry. The work involves simulating real-world conditions in an effort to understand the behavior of the catalyst and improve its efficiency.

In chemical manufacturing, metal catalysts are used to facilitate chemical reactions that wouldn’t otherwise occur, or ensure reactions follow desirable reaction pathways. For instance, creating ethylene oxide, a chemical used in everything from plastic bottles to antifreeze, involves a silver catalyst. In the presence of a silver catalyst, ethylene combines with oxygen to form ethylene oxide rather than combusting to form carbon dioxide, which is an undesirable product.

However, the properties that determine the efficiency of chemical reactions are highly dynamic, Filie explained. Fluctuations in temperature can cause the chemical composition of alloys to change, produce more waste, or cause the reaction to stop working entirely.

By studying catalysts under real-world conditions, with high temperatures and harsh chemical environments, scientists could develop ideal surfaces to facilitate optimal reactions. That could enable manufacturers to heat reactors to lower temperatures, reducing CO2 emissions, or use less energy separating unwanted waste products from desired chemicals.

Filie hopes her work in the Friend Lab ultimately helps chemical manufacturers reduce their carbon footprints, leading to a cleaner environment. (Photo courtesy of Amanda Filie.)

Designing catalysts so they meet the needs of manufacturers is challenging, since materials must be affordable and easy to integrate into existing processes, Filie said. Another challenge is the field’s interdisciplinary nature, which involves collaboration among physicists, chemists, and engineers.

“Being able to coordinate the perspectives, insights, and ideas of scientists from all three fields is incredibly important and exciting,” she said. “Sharing information across disciplines, you get a lot of synergy and innovative ideas, and you see problems in a completely different way.”

With her mind often wrapped around chemical and mathematical challenges, she draws energy and enthusiasm from an unlikely place—the competitive ballroom dance floor.

Filie’s interest in ballroom dancing was sparked by the film “Shall We Dance?” She joined the University of Maryland’s ballroom dance team to learn the steps, and soon found herself drawn in by the glitz, glamour, and camaraderie of the competition circuit.

Moving as a team of two offers valuable lessons in collaboration, she said, and perfecting a dance involves a great deal of intricate work and patience, not unlike the daily challenges she encounters in the lab.

Filie’s interest in ballroom dancing was sparked by the film “Shall We Dance?” (Photo courtesy of Amanda Filie.)

“But the main overlap I see between ballroom dancing and research comes from my philosophy that, if I am going to do something, do it 100 percent,” she said. “There is always something to improve in terms of dancing, which is exciting to me. It is a journey of learning more about yourself, and how to express yourself. It is an awesome, continuous challenge.”

Though Filie’s dream is to someday make the professional dance competition circuit, her career goal is to enter academia. She hopes to conduct research that could contribute to a cleaner environment and also inspire students to always strive for their best in whatever avenue they choose.

Press Contact

Adam Zewe | 617-496-5878 | azewe@seas.harvard.edu