News

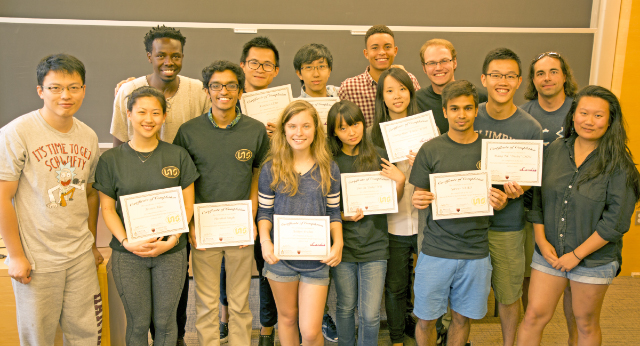

Two teams, comprised of students from SEAS and Hong Kong University of Science and Technology, get ready to race the personal electric vehicles they designed and built through a collaborative summer engineering program. (Photo by Chen Li.)

In a flurry of twirling wrenches, spinning screwdrivers, and smoldering soldering irons, the pit crew attacked the vehicle chassis with a mixture of unbridled ferocity and surgical precision.

But the race was still two days away and the track, not a NASCAR speedway, would be an open area behind Pierce Hall at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS).

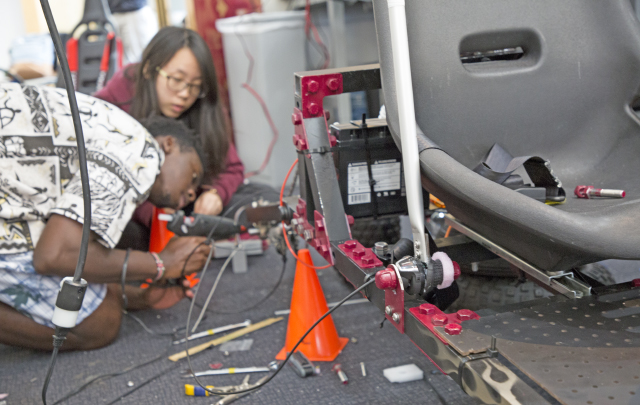

This “pit crew” was actually a team of engineering students, comprised of SEAS concentrators and students attending Hong Kong University of Science and Technology (HKUST), putting finishing touches on the personal electric vehicle they had built during the prior seven weeks as part of a cross-cultural collaborative summer program.

Members of the Team Cardi 'pit crew' prepare their personal electric vehicle for the upcoming race. (Photo by Adam Zewe/SEAS Communications.)

Their journey to the finish line began in mid-July in Hong Kong, where student teammates from Harvard and HKUST met for the first time. They immediately began conceiving personal electric vehicles from the wheels up. Simple requirements—spend no more than $1,500 to design and build a safe, stable, and energy-efficient vehicle—quickly gave way to a challenging execution.

After planning to use aluminum almost exclusively to reduce weight, Team Uno ran into a roadblock when the metal gear shaft snapped under pressure. They had no choice but to replace it with a steel shaft, which provided the needed stability, but added weight to the chassis.

Instead, they focused on a unique plan to improve maneuverability. Drawing on fire truck designs, teammates developed a second motor that maneuvers the back wheels to match the front-wheel angle during a turn, creating a tighter turning radius.

“We’d never seen this design element in a go-kart before,” said Harshal Singh, A.B. ’20, a computer science concentrator. “This increased the complexity for us a bit, but it was a lot of fun to design a new system that would power a wheel while enabling it to turn. The big challenge was to do that as simply as possible.”

Harvard SEAS students enjoy the sights by boat during their visit to the Hong Kong University of Science and Technology. (Photo by Li Chen.)

As they brought their designs to life, each team benefitted from the opportunity to complete fabrication work at the Autodesk BUILD Space in Boston. With access to specialized tools, like a water jet, as well as a plethora of 3D printers, laser cutters, lathes, saws, and drill presses, students crafted custom parts for increasingly complex vehicles.

Across the shop floor, Team Cardi opted for increased speed over maneuverability, retrofitting their vehicle with a heavier seven-speed transmission.

One of their biggest challenges originated in the motor controller, which was destroyed by short circuits. Teammates put their heads together to devise a quick solution; they crafted an acrylic housing for the mounting circuit to avoid future motor controller shocks, explained Ashlyn Frahm, S.B. ’19, an electrical engineering concentrator.

She recalled a marathon eight-hour soldering session as teammates scrambled to remedy the shorting circuit board.

“I’ve learned so many valuable skills this summer, in terms of machining and building circuits,” she said. “But I also learned about collaboration. Individually, everyone can have really great talents, but as a group, everything comes together so much easier. Those individual talents are brought out when you have something to accomplish together.”

Computer science concentrator Harshal Singh, A.B. ’20 (left) and mechanical engineering concentrator Tony Turner, S.B. '19, work on their vehicle's chassis at the Autodesk BUILD Space in Boston. (Photo by Adam Zewe/SEAS Communications.)

Yawer Saad, a junior studying civil engineering at HKUST, agreed that effective communication and balanced decision making helped his team achieve seemingly impossible goals in such a short time.

“The exchange of cultures has been so meaningful it is hard to put into words,” said Saad, a native Pakistani who made his first trip to the U.S. for the summer program. “Different students came together to work on an engineering project, but we ended up learning so much from each other.”

Now in its fourth year, the program’s mission is to empower students to develop the creative skills of engineering design and fabrication, accompanied by an equally important understanding of communication and collaboration, said Evelyn Hu, Tarr-Coyne Professor of Applied Physics and Electrical Engineering.

“Understanding different points of view, whether in engineering design approaches, or cultural context, is critical for today’s engineers,” Hu said.

Team Cardi driver Ashlyn Frahm, S.B. ’19, an electrical engineering concentrator, tries to outrace Evelyn Hu, Tarr-Coyne Professor of Applied Physics and Electrical Engineering. (Photo by Li Chen.)

The chance for the students to interact with industry is also a highlight of the program, she said. They visited TENCENT and Huawei in Shenzhen. While working with Autodesk in Boston, the students used company’s collaborative and “generative” computer-aided design tools.

Hu also praised the teaching and mentoring resources provided by mechanical engineering concentrator and teaching assistant Shuya Gong, S.B. ’17, Chris Lombardo, Associate Director for Undergraduate Studies in Engineering Sciences, Nathan Taylor, Lecturer on Engineering Sciences, and Avi Uttamchandani, as well as teaching fellows and professors at HKUST. The program also benefitted from the SEAS Active Learning Labs, their staff, and resources.

Cutting-edge science delivered direct to your inbox.

Join the Harvard SEAS mailing list.

Scientist Profiles

Evelyn Hu

Tarr-Coyne Professor of Applied Physics and of Electrical Engineering

Press Contact

Adam Zewe | 617-496-5878 | azewe@seas.harvard.edu