News

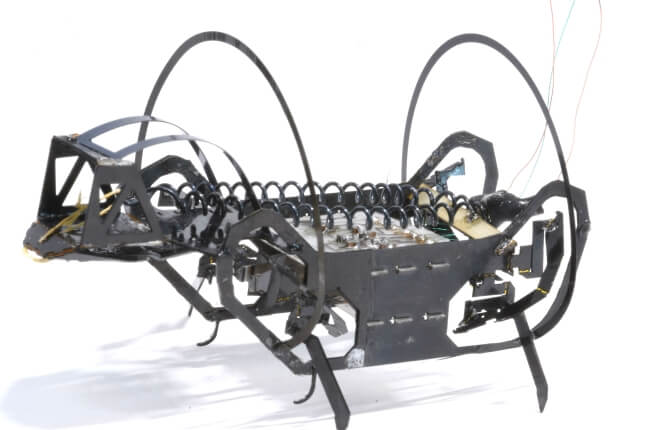

When agitated in an ultrasonic bath, this 2D structure pops-up into a boxy 3D sensor via an integrated spring. With a footprint of 2.7mm, the sensors are small enough to pass through the working port of an 8.6mm endoscope. (Video courtsey of Joshua Gafford/Harvard SEAS)

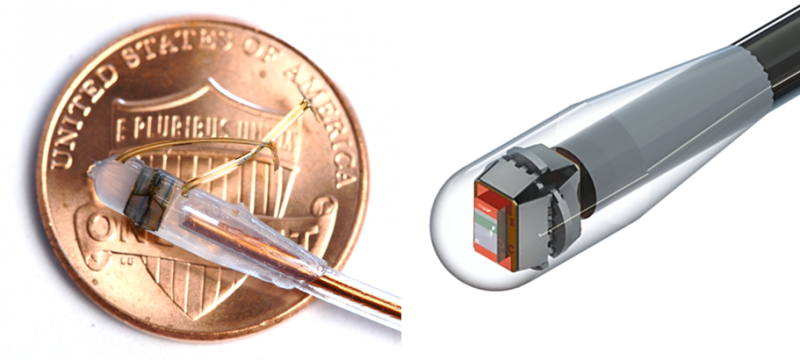

Image of the sensor encapsulated into the catheter with a US penny for scale, and (right) a photorealistic rendering of the molded system.

Robots have taken over the O.R.

Today, more and more surgeries are performed from behind a computer console as multi-million dollar, multi-armed surgical robots like the Zeus or Da Vinci systems replace hand-held scalpels. These robotic systems have been shown to reduce hospital stays and the likelihood of error and infection, while increasing a surgeon’s field of vision and range of motion inside the body. New flexible and soft robotic tools that can snake through twisting and hard-to-reach areas of the body offer even more promise.

But, despite advances in surgical robotics, there is still something human hands can do better than robotic arms: feel. So far, no robotic tool can match the human hand in its ability to sense and adjust force.

That might be about to change.

Recent research from the John A. Paulson School of Engineering and Applied Science and the Wyss Institute for Biologically Inspired Engineering explores a new method to build low-cost, millimeter-scale force sensors. The research, authored by graduate student Joshua Gafford; Robert J. Wood, the Charles River Professor of Engineering and Applied Sciences; and Conor Walsh, Assistant Professor of Mechanical and Biomedical Engineering, was recently published in IEEE Sensors Journal. Wood and Walsh are both Core Faculty Member at the Wyss Institute for Biologically Inspired Engineering at Harvard.

The biggest challenge in developing force sensors for robotic surgical tools is size, said Gafford, the paper’s first author. Soft robotic surgical systems, for obvious reasons, need to be small and the sensors that sit on the system’s robotic fingertips need to be even smaller.

“Current conventional fabrication techniques limit the complexity and the sophistication of these millimeter-sized sensors while significantly driving up the cost of assembly and implementation,” said Gafford. “This poses a barrier to widespread adoption of force-sensing soft robotic surgical tools that can perform minimally invasive and complex surgeries in an inherently safe way.”

To solve this manufacturing problem, Gafford turned to a manufacturing technique pioneered in the Wood Lab: pop-up manufacturing. Inspired by origami and pop-up books, this technique fabricates complex micromachines by layering laser-cut materials into thin, flat plates that pop up into a complete electromechanical devices. This fabrication approach has the potential to remove the human element from the assembly process by allowing devices to ‘build themselves,’ significantly driving down the cost of manufacturing.

The sensor consists of four layers of laser-machined stainless steel sandwiched together and laminated with a flexible polyimide layer to facilitate self-assembly, and copper to provide electrical contacts. When agitated in an ultrasonic bath, this 2D structure pops-up into a boxy 3D sensor via an integrated spring. With a footprint of 2.7mm, the sensors are small enough to pass through the working port of an 8.6mm endoscope.

The sensor uses a principle called light intensity modulation (LIM) to sense force at the millinewton level. LIM works by connecting a light emitter and a light detector with an elastic element. When force is applied, the elastic element deforms, bringing the emitter and detector closer together. The change in irradiance sensed by the detector can be translated into applied force.

The next step in the research, said Gafford, is to make the sensor even smaller and more robust, eventually providing flexible surgical robots with a sense of ‘touch.’

“This manufacturing technology could be a disruptor in the surgical robotics field,” said Walsh. “It will enable new possibilities for sensors and end-effectors that can be placed at the tip of flexible surgical tools.”

“The ability to rapidly and inexpensively create millimeter-scale surgical tools with embedded sensors and actuators will find numerous applications in laparoscopy and endoscopy,” says Wood.

Topics: Robotics

Cutting-edge science delivered direct to your inbox.

Join the Harvard SEAS mailing list.

Scientist Profiles

Robert J. Wood

Harry Lewis and Marlyn McGrath Professor of Engineering and Applied Sciences

Press Contact

Leah Burrows | 617-496-1351 | lburrows@seas.harvard.edu